“In the midst of every crisis, lies great opportunity.” -Albert Einstein

My now business partner and I have been workout bros since 2013. Takeo and I met at a local crossfit gym in Miami, but it wasn’t until about 2 years ago that we became business partners. In March 2020, with gyms closed and fitness equipment impossible to find, we had to get creative with our workouts, so a week into the Covid-19 quarantine we picked up a few cinder blocks I had in my backyard and we started using them to workout with. Although the cinder blocks were rough on the hands, we found them to be an extremely versatile and functional strength training tool.

We jokingly began calling our weekly cinder block workouts CinderFit. A few friends from the gym started to join us for the weekly outdoor CinderFit workouts which involved a farmers’ carry around the block a couple of times and stopping to complete 9 exercise stations along the way:

- 30 x thrusters

- 30 x deadlifts

- 30 x plyo-push ups

- 30 x overhead lunges

- 30 x squats

- 30 x presses

- 30 x cinder block swings

- 30 x step-ups

- 30 x dips

We also discovered there was an entire subculture of fitness enthusiasts posting cinder block workouts online. Takeo has a background in product development and for the last ten years his company, i2GO, has been designing and manufacturing electronics accessories in China for wholesale in Latin America. With his product design background, Takeo suggested that we design cinder blocks to workout with. I told him he was crazy.

In my 20’s I served as a Peace Corps volunteer in Guatemala where I saw the ubiquitous cinder block was used not only for constructing buildings, but for furniture too. During my time in Guatemala, I saw cinder blocks used as shelving, beds, benches, etc. In many ways the cinder block has quite a beautiful, yet simple, modern design to it.

When we returned to the gym in June 2020, one of the members brought a 55 lb SPARTAN RAMroller to the gym. This was our “aha-moment”. The RAMroller cost $140 and could do a fraction of what a well designed cinder block could potentially do.

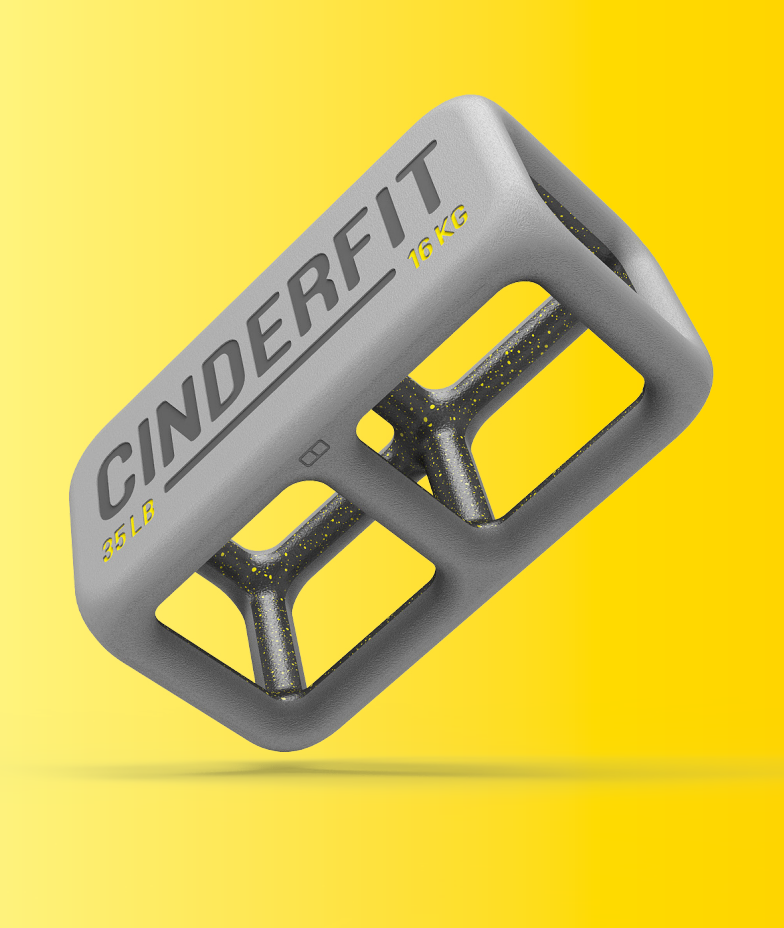

We decided to engage with a couple of amazing Italian industrial designers that Takeo had met on one of his business trips to China. The direction we gave the designers was simple: let’s design a cinder block, made out of steel, that can do just about everything a kettlebell can do. We asked them to also figure out a way to attach resistance bands to the blocks. Also, a flat surface for step-ups was a must, but first and foremost the block must look like a piece of furniture. We asked them to design a workout tool that would look beautiful in a studio apartment. About a month later, this is the original design they came up with…

Building The CinderFit Team

There were five of us that had come together to work with the Italian designers. Early on we had incredible support from a couple of friends (Dave & Loida) from our gym that had decades of combined experience in the fitness industry. My neighbor and friend (Ned) just so happened to be the Senior Vice President of Marketing for Bacardi. Ironically, Ned saw the very first CinderFit workout while he was sipping coffee on his front porch. When we brought up the idea of launching CinderFit he thought the idea was crazy enough to work and that’s how we started to build the CinderFit brand.

Product Validation

In one way or another we looked at the existing concrete cinder block as a MVP (Minimum Viable Product). We already had some form of product validation since there was a subculture of fitness enthusiasts that already used concrete cinder blocks as an exercise tool. By late February our first cosmetic prototype arrived. With our prototype in hand, we photographed dozens of exercises with the CinderFit block prototype. We then meet with 100+ personal trainers and gym owners in Miami to get their feedback on the product. It was time to find a supplier.

Manufacturing

With Takeo’s relationships and his manufacturing experience in China we were able to source a factory by July 2022. With travel to China completely restricted, developing an entirely new fitness product category without face-face time would be challenging. Luckily we had trusted partners in China that could visit factories and take care of quality control on our behalf. By August we had our first factory samples in Miami.

There were some production challenges to overcome, but by working with a thoughtful production engineer, the final product turned out better than we had first imagined. By October we had received our final “golden samples” and we pulled the trigger on our first order of CinderFit blocks in early November.

Hammer Time

Our first shipment of blocks arrives this week. We’ve pre-sold about 100 blocks so far to friends, personal trainers, physical therapists and gyms. Let’s see what the market says, but we have a good feeling that we can turn the CinderFit brand into something special. So far they are selling like hot cakes. Place your order here before we’re sold out!

CinderFit 305 Gym

We recently opened a flagship CinderFit 305 gym. Come check us out. We’re hosting our launch event at the CinderFit 305 gym on 4/23. You can RSVP here.

Let’s Build!